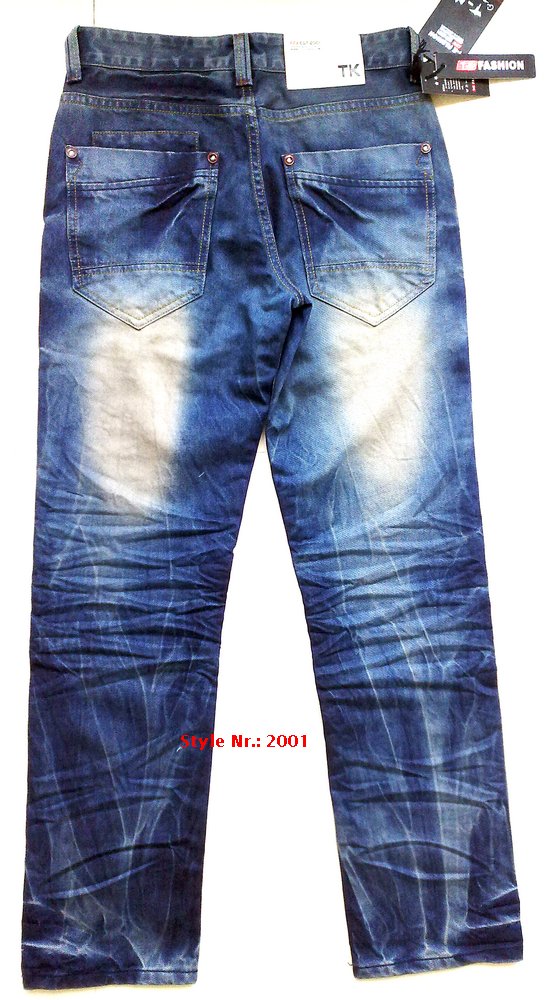

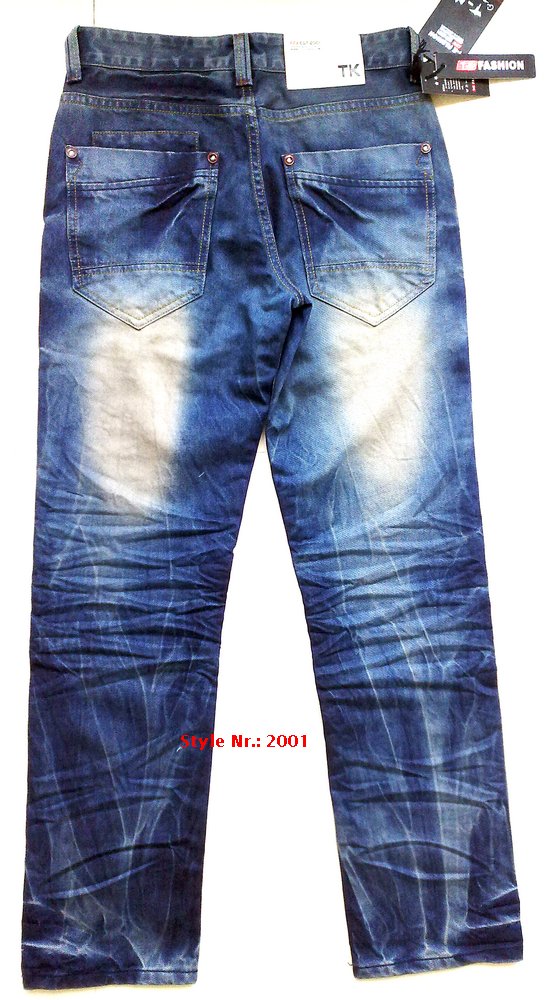

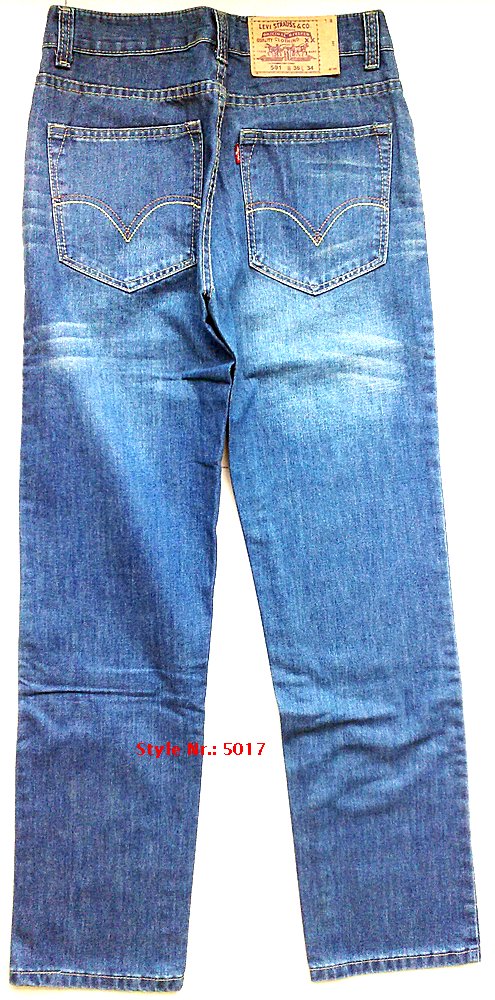

Jeans

manufacturing

To produce a pair of a pair of traditional jeans, following

techniques are required. The sewing process alone takes between 12 and

15 different types of sewing machines, special equipment for attaching

the trims will also be necessary. To save time and materials it's best

to have the machinery for the different operations already set up.

Some

machines

may require up to 4 or 5 thread spools to create one stitch. Setup and

advance planning can get pretty complex especially if the designer

wants to have several contrasting color threads for the stitching

throughout the blue jean garment. Each operation would be set up

separately because there are different color threads required for

different parts of a blue jean garment. There are also a variety of

stitches required for different parts of the garment for functional

reasons.

For

example

the hem might use a chain stitch and a seat seam may need a felled

stitch for reinforcement since that part of the denim jean garment has

greater stress from the wearer. One area may need a single needle

stitch where another area might use a double needle stitch. I have

learned from the mass production processes that it becomes more cost

efficient when an assembly line scenario is utilized and the best way

to keep costs low for the consumer is to make mass quantities.

Jeans denim,

jeans, designer jeans, celebrity clothing, red carpet fashion, Export

Jeans

The stitch complexity used in creating a pair of jeans is far greater

than that of sewing together a custom suit!

As mentioned above a designer may choose to use a variety of thread

colors throughout the denim jean so the more complex the thread color

combinations the more expensive the construction will be. A greater

inventory of threads needs to be kept and a higher skill level employee

would be required to sort out the thread layout.

Cost considerations include stitches per inch. The higher the stitch

count, the more expensive it will be to construct a garment since there

is greater thread consumption. It may also be interesting to note that

not only is it important to be watchful of the stitch count on one

machine type but to have all machines used in constructing that garment

to have a similar stitch length so their is a consistency throughout

the garment.

|